Maximize Efficiency and Innovation with Processall: The Industry Leader in Purpose-Built Mixing Solutions

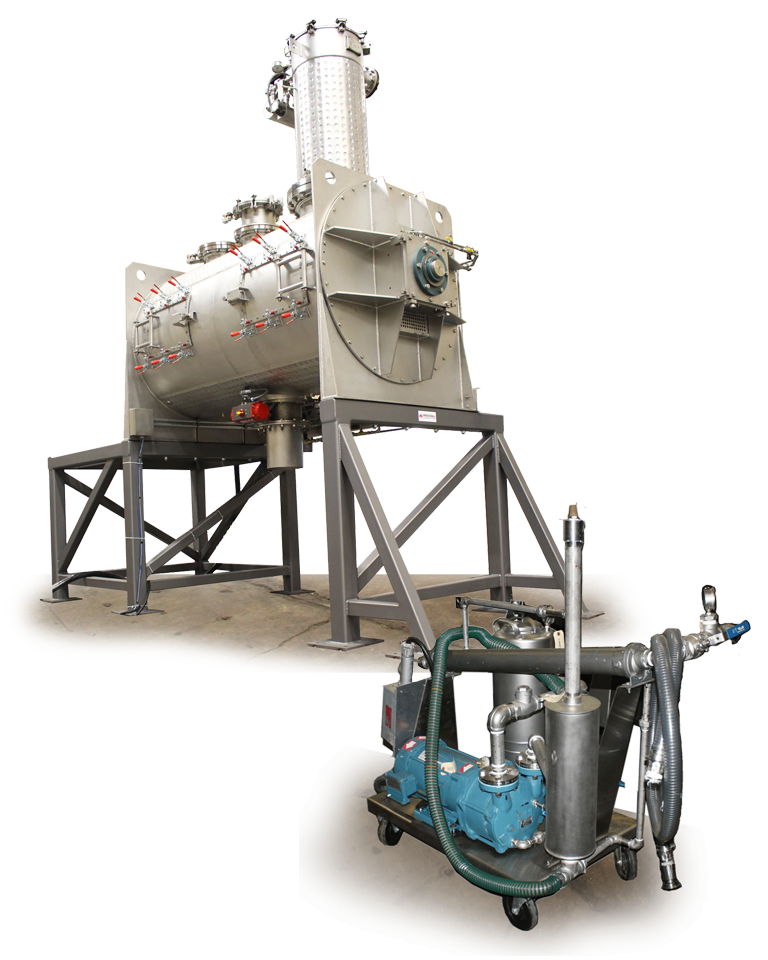

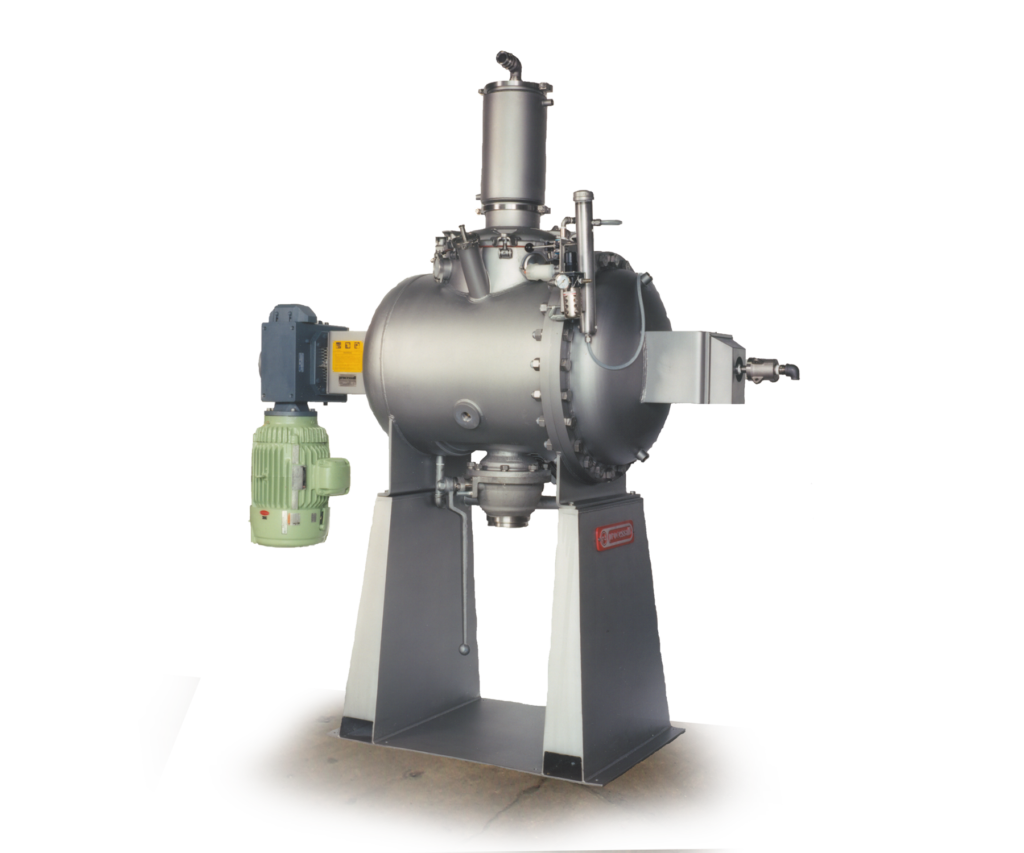

Experience unmatched efficiency with Processall’s innovative plow mixers and reactors, purpose-built to optimize processes across diverse industries and applications. Our proven track record is evident in the hundreds of plow mixers, dryers, reactors, and amalgamators supplied to industry leaders globally. Catering to lab scale to production scale, our capacity range spans from 1L to over 25,000L. Known for superior efficiency and precise control, our equipment dramatically cuts processing time and energy costs, accelerating your path to market with high quality products. Embrace the future with our Industry 4.0 integrated systems for smarter, remote operation and tailored plows for diverse applications. Choose Processall, where innovation, quality, and efficiency are not just promises, but realities in industrial processing.

Did you know that Processall is a key supplier to battery companies for the manufacturing of cathode material?

More Than Just a Plow Mixer, it’s a Purpose-Built Comprehensive Solution

• Our mission is to empower businesses with advanced mixing and reacting equipment, designed to minimize bottlenecks and accelerate getting your products to market.

• Our equipment masterfully combines mixing, blending, pressure reactions, vacuum, jacketed drying, and cooling into one powerful unit.

• Processall leads the industry with equipment that cuts processing times by an average of five times.

• We help streamline your process, so you can save on investment, reduce floor space requirements, and cut maintenance time and costs.

• As industry leaders in plow mixing and reactor technology, we’ve set a standard in efficiency and precision, serving a wide range of industries including pharmaceuticals, chemicals, and food processing.

Optimized Performance over Longest Equipment Lifecycle

• Based on proprietary calculations, rigorous lab testing, and decades of engineering expertise, we ensure that our equipment is perfectly sized for your needs, all but eliminating the risk of under or over-sizing.

• At Processall, we meticulously select and instrumentally analyze each material for superior composition and grade, ensuring unmatched quality and performance.

• Our proprietary Proseal™ seals guarantee the longest-lasting seals in the industry, significantly reducing downtime and maintenance costs for uninterrupted productivity.

• Our Proseal gaskets are purpose-selected based on customer applications to further improve productivity.

• Featuring Variable Frequency Drive (VFD) controlled motors precisely programmed to each application, our mixers optimize energy usage.

Experience Unmatched Efficiency and Quality with Processall’s Streamlined Manufacturing

• Processall takes pride in our comprehensive in-house manufacturing, enabling full control over our supply chain, which translates to consistently high-quality products and the fastest delivery in the industry.

• Our commitment to excellence is evident in every aspect of production – from manufacturing each major component under one roof to conducting thorough full factory run-offs. This meticulous process ensures that each product meets our superior quality standards, significantly reducing installation time.

• The combination of expert installation supervision, global facility presence, and our rigorous manufacturing control means our customers enjoy faster setup, exceptional quality, and equipment tailored to their specific industrial needs.

• With Processall, you gain not just equipment, but a promise of rapid, efficient production and a swift market entry, backed by the confidence that every piece meets the highest standards of performance and reliability.

Maximize Production Efficiency with Comprehensive Turn-Key Solutions

• Our sister division, Armor Aftermarket, offers an extensive range of services, including tear-outs, reassembly, installation, parts, repair, construction, and rebuild services.

• We offer a comprehensive range of turn-key solutions minimizes lead time and downtime, allowing customers to focus on core business operations.

• Our experienced and efficient equipment installations, maintenance, and repair services help reduce downtime, ensuring our customers’ production lines run smoothly.

• We also proactively sell spare and replacement parts, ensuring that our customers have everything they need to keep their equipment functioning at optimal levels.

• Our seamless process minimizes disruptions and maximizes production efficiency for our customers, with the highest level of service and support.