Cocoa & Chocolate

Save space and time with Processall’s Pretovac Reactor

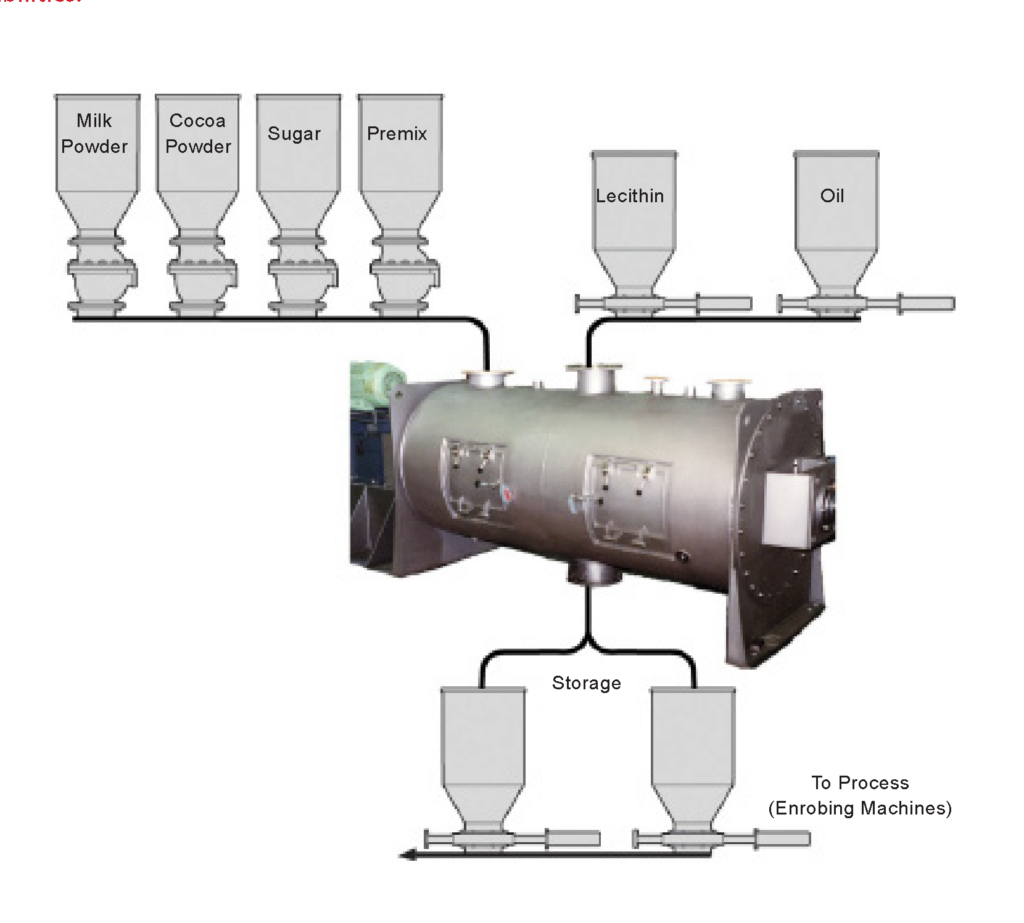

Processall’s Chocolate Processor is capable of performing as a combination mixer, refiner and conch. The fluidized bed mixing, combined with built-in extra high shear mills, provides the

chocolate industry with the most universal tool. This one processor reduces costs by eliminating several pieces of equipment, saving space and reducing material handling.

Chocolate flavored compound coating prepared in a Processall Mixmill® Mixer:

Dry ingredients can be charged to the Processall Mixer after all liquid ingredients added. With the aid of the high intensive mix action of the plows, the dry ingredients are dispersed and wet milled simultaneously. This process eliminates the need for premixing, dry milling, dust collection system and pneumatic handling. This results into a very smooth, high quality dispersion; all accomplished in a short processing cycle. Processall

manufactures mixers from 4 liters to 25,000 liters in size.

Processall Prestovac Reactor Capabilities:

• Thorough Intensive Mixing

• Dispersion

• Wet Milling

• Pressure Cooking

• Vacuum Drying

Additional areas Processall can contribute

to the chocolate technology:

Alkalization (Dutching)

• Improved Taste

• Improved Solubility and Suspension

• Color Development

• Bacteria Reduction

Sterilization

• Micro Organisms Killed or Inactivated

• Use of Steam in the Process

Instead of Ethylene Oxide

• Quick Steam Diffusion

• Moisture Can be Removed, and Product

Dried in the Same Vessel

Agglomeration/Wet Granulation

Typical applications :

Food

Food products are frequently agglomerated and/or encapsulated to increase their dispersion rate in liquids. Fruit and chocolate drink mixes, for example, must “dissolve” quickly with minimum stirring.

Pharmaceutical

Pharmaceutical granulation produces the material handling characteristics and absolute uniformity of die-fill needed to assure rigid dosage accuracy on high-speed tableting presses.

Chemical

In the chemical industry, agglomeration controls dusting of such materials as fly ash, fertilizer, and other hazardous powders.

Ceramics & Powdered Metal

Powdered metal and ceramics processors granulate to prevent

component segregation, to improve material flow, and to adjust density to modify die compression ratio.

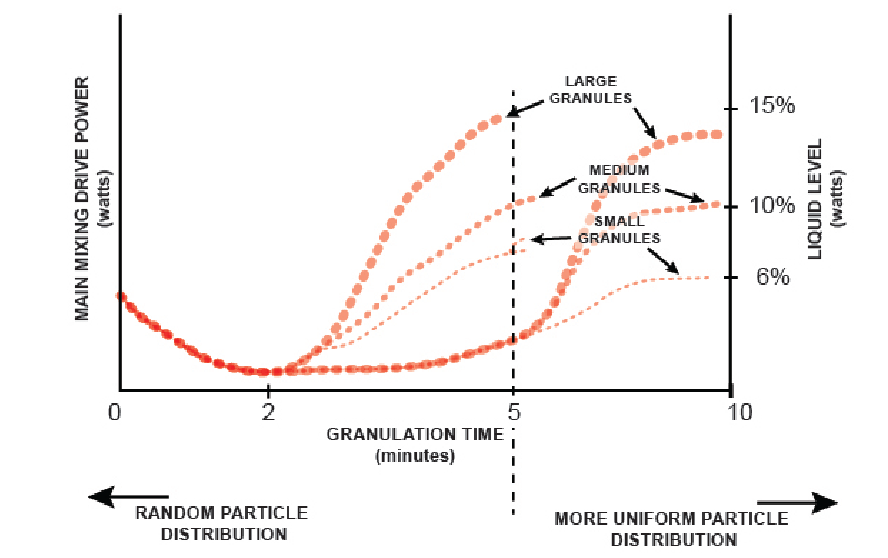

Typical Agglomeration

Wet Granulation Curve

In Processall’s Mixmill® line of mixing granulators, medium-density blending elements lift and disperse the product to produce a mechanically fluidized bed, which rapidly and efficiently blends materials of widely different density and particle size, while an integral high-intensity chopping mill system distributes the agglomerating solutions while binding and controlling particle size. Post milling is usually unnecessary.

The highly efficient chopping mills often permits the use of less granulating solution and eliminate the need for subsequent drying. When post-drying is necessary , a Processall Mixmill® equipped with a heated jacket takes advantage of the excellent heat transfer rates of the fluidized bed systems to rapidly and efficiently dry the agglomerated product. Processall can provide a complete vacuum drying system with solvent recovery/reuse capability.

Vacuum drying after pharmaceutical granulation in a Processall Mixmill® improves particle size distribution reproducibility. Processall maintains a well-equipped testing laboratory and a rental fleet dedicated to process and development requirements.