Food & Nutrition

The advantages of the MixMill process

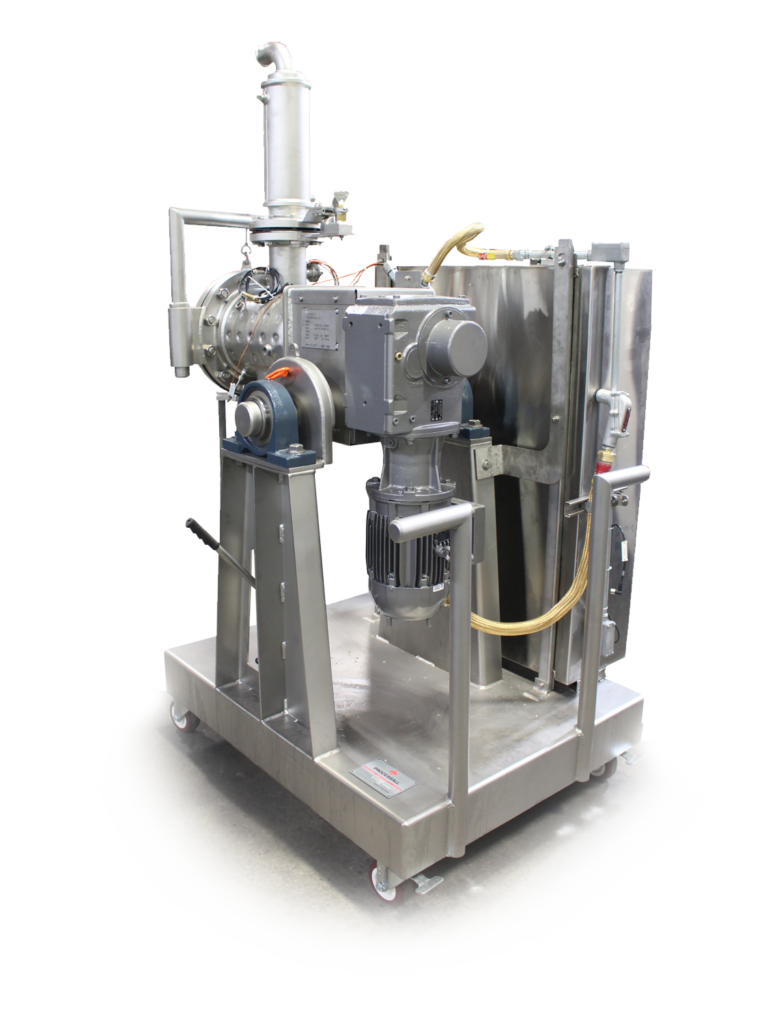

Processall MixMill mixers successfully process a variety

of food products where the combined mixing and milling

actions of the Mixmill allow several process steps to be

performed in a single vessel.

The Mixmill’s medium- intensity blending elements lift and disperse the

product in a “mechanically fluidized bed” which efficiently and rapidly

mixes materials of widely different density and consistency. Another

system of integral high-intensity chopping mills controls particle size

and breaks agglomerates. Combined with heating, cooling, drying and

liquid- addition capabilities, Processall Mixmills find multi-purpose use

in such applications as:

Bakery & Doughnut Mixes

The Mixmill disperses high levels of liquid and solid shortening without forming agglomerated prills or “fish-eyes”. Post-finishing is usually unnecessary.

Dry Blended Soups

Most dry cup-of-soup products are well suited to the Mixmill.The ability to disperse large blocks of shortening and high-viscosity animal fats makes the Mixmill highly desirable. A three-step process allows finished product to be made in a single process vessel.

Soluble Flavorings

Adding liquid flavors onto carriers requires efficiently distributing small amounts of liquid throughout huge quantities of dry carrier.

The Mixmill’s blending action produces an “expanded’ fluidized bed with the tremendous surface area needed to assure maximum distribution of the flavorings.

Imitation Cheese

In preparing this product, the Mixmill’s unique mixing action disperses the ingredients quickly and efficiently. The product can be sterilized in

the same vessel.

Compound Coatings

Chocolate compound coatings are prepared by mixing hot oils and cocoa powder with other ingredients. The combined mixing and milling action of the Processall Mixmill disperses all ingredients efficiently in a short cycle time.

Instant Beverages and Shakes

For powdered drinks the Mixmill disperses flavors quickly and without loss while the mill spreads coloring evenly throughout the batch.

Nutricious Diet Products

Fibers, cocoa powders, and other hard-to-disperse ingredients are used in the formulation of weight-control and other dietary products. The combined mixing and milling action of the Processall Mixmill blends these ingredients in short process cycles.

The mixer can be used to add moisture and lubricants to aid in the agglomeration process and to maximize the efficiency of expensive

instantizing materials.

Coffee and Tea

Powered ice tea and coffee drinks can be produced in Processall’s Mixmill. The gentle action of the main mixing elements used alone

eliminate breaking particles while producing thorough blends.