Liquid Filtration &

Drying Filt-A-Dry

The advantages of the MixMill process

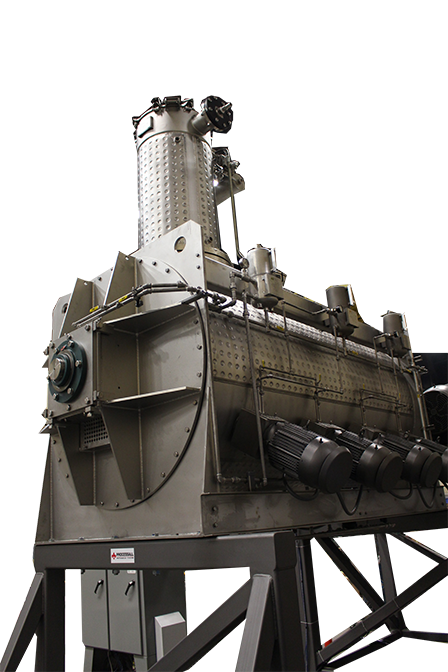

The Filt-A-Dry is designed to provide more versatility to Processall’s arsenal of process equipment.

With the capability to mix, slurry, filter and dry in one vessel, less pieces of equipment are required

to do the job. This will ultimately save space, money and still provide excellent efficiency.

Principle of Operation

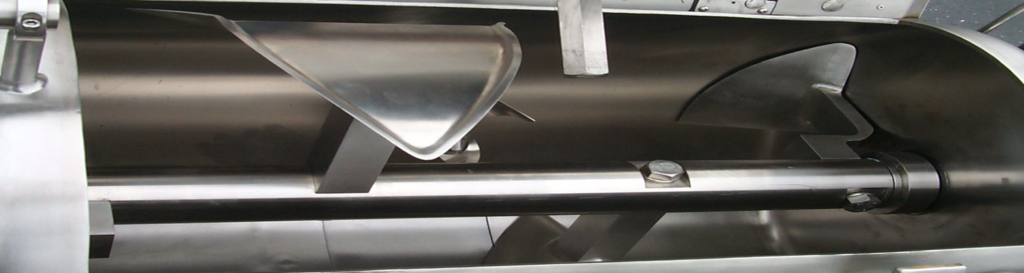

The machine is designed with filter sections attached to the lower quadrant of the processing vessel. The filter elements are easy to change without entering the machine. Quick screen changes is one of the major attributes of the

Filt-A-Dry. Backflushing of the filter is occasionally used to clean pores and avoid blockage. With the excellent mix action in the Processall vessel, the filter cake is freshly renewed to allow for better extraction. Additional slurrying and washing steps can be conducted in the same vessel. The filter cake can be vacuum dried after the filtration step.

Some of the advantages

of this system

1. Multi-processing in one vessel.

2. Eliminate product handling between

washing and drying steps.

3. Less space is required to accomplish all

the processing in single machine.

4. Excellent drying capabilities with Processall

mechanically fluidized action.

5. Better environmental containment with

a closed system.

6. Single supplier for the filter/dryer and

ancillary equipment makes it easier for the user

to maintain the equipment and get quick

answers to their processing needs.