In 1996, when California legalized medical marijuana, the demand for marijuana and marijuana-infused products exploded. Currently, 72% of the states in the United States have either decriminalized cannabis or permitted it for medical issues. During this time many companies began to strike gold in this exploding market, and some have even grown large enough to be featured on the New York Stock Exchange. With corporations like Heineken, Anheuser-Busch, and Scott’s Miracle-Gro, entering the cannabis and cannabis extraction markets need to optimize extraction methods is going to become more paramount for long-term success. Processall has years of experience in everything from steam injection extraction, to maceration (organic solvent-based) extractions, to help improve processing time for our clients. Our equipment offers unique abilities due to the fluidized bed nature of our extractors, which greatly improves the efficiencies of oil separation from biomass materials.

Plow mixing extraction enabled a client of ours to reduce the processing time of vanilla extraction from three weeks to ten hours. The reason for the major time reduction is the fluidized bed maximized the potential solvent contact points and enabled faster extraction. Additionally, the solvent was able to be filtered out of the vessel soon after the oils had been dissolved in the solvent medium, and more solvent could be injected into the system to repeat the extraction process. At the end of the process, the residual solvent in the biomass material is removed by pulling the unit under a vacuum.

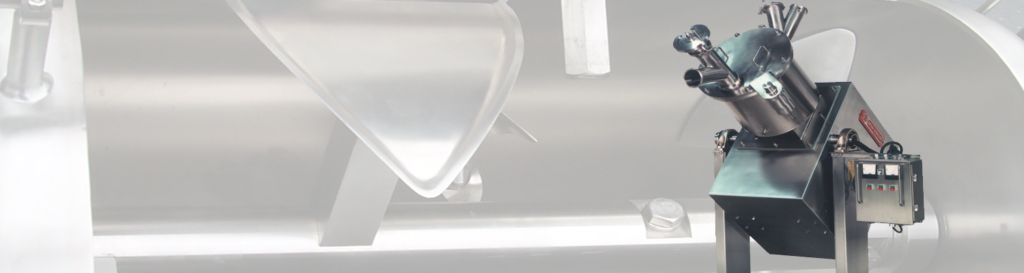

Processall employees have a long history of working with companies in all markets, aiding in everything from initial testing to installation of the unit, to maintenance throughout the life cycle of the unit.

Processall’s Plow Mixing technology gives CBD manufacturers a leg up on the competition. Below are some of the benefits of moving toward plow mixing technologies for the extraction industry:

- Faster extraction of essential oils from the system than other methods, because the fluidized bed maximizes solvent contact points

- High heat transfer rate because of the creation of a mechanically fluidized bed within the drying vessel

- The vessel jacket allows different media (hot oil, steam, or tempered water) to be used, depending upon the thermal sensitivity of the product

- A vacuum lowers the vapor pressure of the liquid, facilitating quicker drying times.

- Allows for the collection of volatilized liquids

- Thermal jackets to allow for optimal temperature controls

- High-speed mix handles materials as fine as dried oats, without damaging the material

- Easy to scale up and predict extraction and drying times after lab testing

- Ability to remove water or organic solvents from material

- Vessels can be further outfitted to increase versatility:

- Mechanical seals – will allow the vessel to be pressurized as well as reach a low vacuum (28 Hg)

- Liquid lances – allows media to be sprayed onto the substrate

- Ability to perform extraction and drying within one unit resulting in:

- Faster throughputs

- Reduced material handling

- Reduced energy consumption

- Less equipment on the production floor

Other extraction markets currently using plow mixer technologies:

- Vanilla Bean Flavor Extraction

- Coffee Bean Decaffeination

- Floral Scent Extraction

- Pine Oil Extraction

- Fruit Flavor Extraction

- Cocoa Extraction

- And many more

Processall maintains a fully equipped testing facility in Cincinnati, Ohio designed to provide customers with the data they need to develop their process, evaluate equipment, scale up, and identify the necessary equipment to maintain desired production volumes. We extend an open invitation to all potential customers to bring their products to our test center and get a “hands-on” experience with our technology and capabilities.

We also maintain a rental fleet that customers can utilize to do further testing at their facility or employ to minimize their startup costs for a new process.

Please feel free to contact us with all your material processing questions and our experienced industry professionals will help you find the right mixing solutions for your application.