As the New Year unfolds, many embrace a commitment to health by turning to nutritional supplements. This surge in demand has propelled the nutraceutical market’s growth in the past two decades. Various factors, including post-holiday upticks, continuous material discoveries, and a global health focus, contribute to the industry’s expansion.

The Nutraceutical Landscape

Beyond seasonal upticks, a multitude of external factors shape the nutraceutical industry. Daily discoveries of new materials promoting a better standard of living drive the market’s constant pursuit of innovative ways to incorporate these findings into products. A growing preference for natural alternatives to pharmaceutical medications, particularly among younger generations, intensifies the demand for nutritional supplements at an earlier age. Additionally, a global trend towards personal health improvement opens new markets beyond the United States.

The Role of Plow Mixer Technology

In response to these pressures, companies in the nutritional supplement sector are turning to plow mixer technology. This unique approach enables multiple unit operations within a single vessel, offering unparalleled efficiency and versatility.

Diverse Applications: Plow mixers, such as those offered by Processall, are utilized across industries, from Metal Stearate production to vanilla bean sterilization.

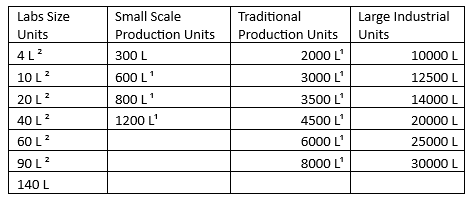

Size Range: Available in various sizes, from 4 L lab units to 30000 L industrial units, accommodating different production scales. All Processall machines can also be purpose built to fit the application requirements. Also, we offer the ability for customers to come in and learn how we customize our machines to fit their specific needs.

¹Come in two different versions– a short compact model and a longer thinner model

² Can be equipped with an optional tilting mechanism

Purpose-Built: Processall plow mixers are purpose-built machines catered to the application to ensure process efficiency.

Enhanced Efficiency and Reduced Times

Mechanically Fluidized Bed: The creation of a mechanically fluidized bed reduces material mixing time significantly.

Dry Powder Blending: Processall plow mixers have demonstrated reductions of up to 2000% in mixing times compared to alternative technologies, enhancing efficiency.

Features Enabling Superior Performance

Temperature Control: Vessel jackets allow the use of different media (hot oil, steam, or tempered water) based on the thermal sensitivity of the product.

Material Handling: Capable of handling fine materials like dried oats without causing damage, ensuring product integrity.

Scalability: Easy scalability after lab testing, with predictable mix times facilitating efficient planning.

Additional Capabilities

U1 Pressure Vessel: Processall plow mixers can be designed to meet U1 pressure vessel standards for enhanced safety.

Outfitting Options: Mechanical seals, liquid lances, and vessel outfitting options increase the versatility of these units.

Processall: Your Partner in Advancing Nutraceutical Production

Processall, a leader in plow mixing technology, maintains a fully equipped testing facility in Cincinnati, Ohio. Our facility invites potential customers to engage in hands-on experiences, allowing you to develop processes, evaluate equipment, and identify the most suitable equipment for your production needs. Explore lab-scale purchases or rental fleet options for cost effective startup.

For all material processing inquiries, reach out to Processall. Our experienced industry professionals stand ready to guide you in finding the optimal mixing and reacting solutions for your specific application. Elevate your nutraceutical manufacturing with Processall’s purpose-built plow mixer technology.