The history of drying foods to extend shelf life is a long and storied one, dating back thousands of years to ancient civilizations such as the Egyptians and Greeks. Early methods of food drying relied on the sun and wind to remove moisture from food, allowing it to be stored for longer periods of time without spoiling. This was a crucial development in human history, as it allowed people to store food during times of plenty to ensure they had enough to eat during times of scarcity. Several popular examples of food that are often dried for times of limited food include the following.

- Jerky: Jerky is a form of dried meat that has been popular for thousands of years. It was a staple food source for many indigenous people, particularly in North America, and helped sustain them during harsh winters and long journeys. It was also a popular food for early explorers and settlers, as it was easy to transport and had a long shelf life.

- Dried fruits: Drying fruits such as dates, figs, and raisins helped ancient civilizations in the Middle East and Mediterranean regions to preserve their harvests for long periods of time. These dried fruits provided a valuable source of nutrition during times of scarcity and were often used in trade and commerce.

- Dried fish: Dried fish has been a staple food source in many coastal regions for thousands of years. It was an important food source for early seafarers and helped sustain them during long voyages. Drying fish also helped to preserve the catch during times when fresh fish was not readily available.

- Dried grains: Drying grains such as rice, corn, and wheat helped ancient civilizations to store their harvests for long periods of time, ensuring a reliable source of food during times of famine or drought. This was particularly important in regions where food was scarce or difficult to grow.

Over time, humans developed more advanced methods of food drying, including the use of specialized equipment such as drying racks, ovens, dehydrators, and vacuum dryers. These technologies allowed for more efficient and controlled drying of foods, leading to improved shelf lives and more widespread use of dried foods. In many cultures around the world, dried foods remain a staple food source to this day, with dried fruits, meats, and grains being popular ingredients in many traditional dishes. Today, modern drying technology has made it easier than ever to preserve food and extend its shelf life, with methods such as freeze-drying and vacuum-drying allowing for even greater preservation of flavor, texture, and nutritional value.

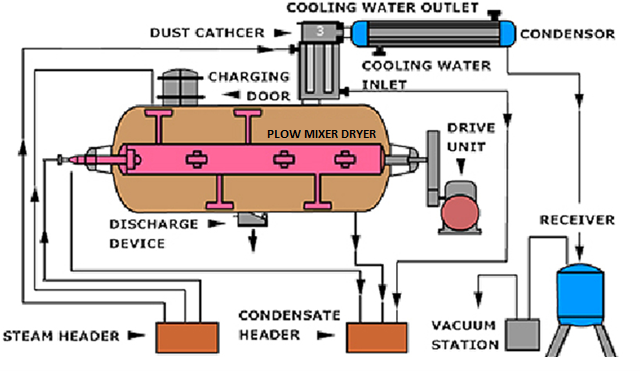

As previously stated there exist a wide variety of drying techniques on the market but few offer the drying speeds of plow share vacuum driers. The plowshare vacuum dryer is a cylinder located on its side with a central shaft having mixing elements or Plows. The spinning of this shaft and plows creates a mechanically fluid bed from the mixing action. This is because of the high horsepower motors used on plow mixers. The mixing action creates a maximum heat transfer rate from the dryer walls to the food that is being dehydrated. The mixing action also continually exposes more new particles to the surface area for vapor removal as agglomerates or lumps are reduced in size. The vessel is additionally put under vacuum to reduce boiling points of solvents and reduce the chances of thermal breakdown of materials. The lowered boiling point also limits the product temperature which protects the food’s purity. All this is done by heating the drum to the temperatures needed to achieve vaporization at low pressure. The vacuum also helps create a path for the liquid to leave the drying vessel and provides a route to recovery of the solvents that are escaping the food. Due to the combinations of these factors, the material achieves quicker drying times because of the high level of surface contact with the vessel’s shell during mixing. (See Fig 1 for an overview of the parts)

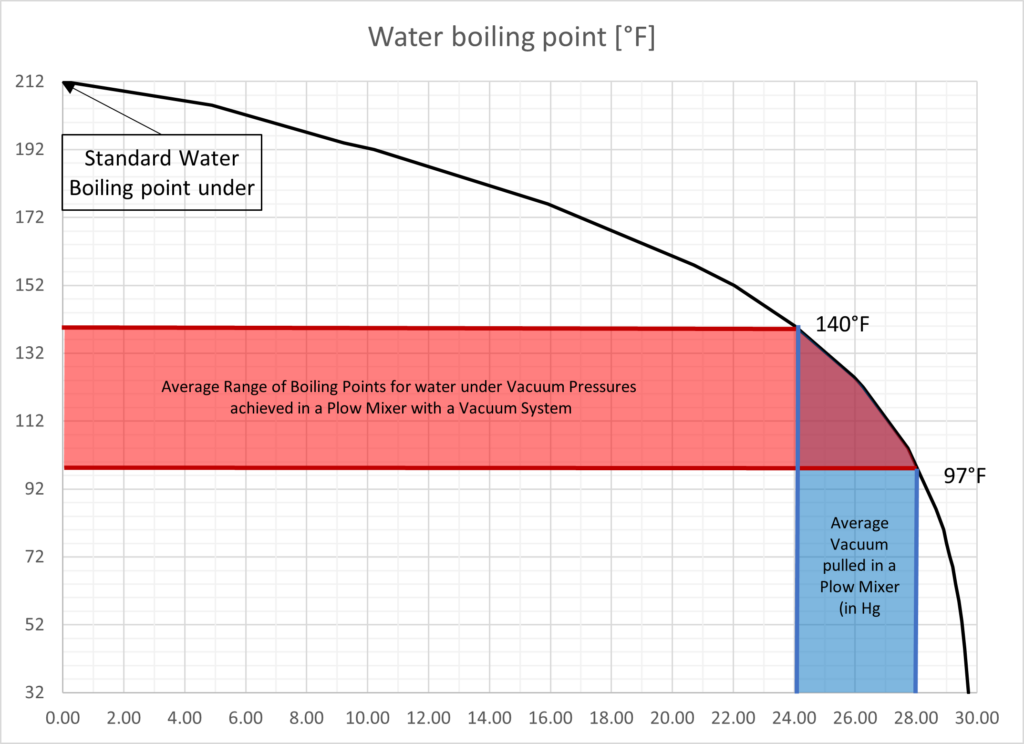

For these reasons, many companies currently use plowshare vacuum dryers to evaporate these residual solvents used after they are done cleansing the product. Vacuum drying with plow mixer technology maximizes the heat transfer coefficient between the jacket and the product while lowering the product temperatures required for vaporization. See Figure 2 for an example of how much lower the boiling point is under Vacuum conditions. (24 in Hg and 28 in Hg are typical vacuum pressures one can achieve in plow mixer vacuum driers)

After reaching the final desired volatile content in the product, the material can be cooled for collection and final packaging without exposing the operator to dangerous conditions. Cooling of the product can also reduce the risk of fire or explosion by exposing the product to the atmosphere which is common in many powder food operations. The vacuum dryer can also be purged with inert gases to reduce explosion risks too. Currently plow mixer dryers are used in a wide variety of the food market. Listed below are just a few examples of industries that have used this drying technology.

· Cranbury Juice |

· Wheat Germ |

· Liquid Smoke |

· Instant Soup |

· Maple Syrup |

· Vanilla Beans |

· Fish Bones |

· Kelp |

· Peppers |

· Cocoa Powders |

· Flax Seeds |

· Cornstarch |

|

Processall’s Plow Mixing technology gives chemical manufacturers a leg up on the competition. Listed below are some of the benefits of moving toward plow mixing technologies for chemical manufacturers.

- High heat transfer rate with coefficients upwards of 50 BTU/(hr•ft²•°F) which increases the speeds of drying

- Lower vaporization temperatures protect thermally sensitive material

- Can be customized with a wide variety of safety features to improve employee safety when handling dangerous materials

- Ability to serve as both a reactor and dryer of materials thus reducing the need for multi-unit operations. (Many vanilla bean extractors use plow mixers because of these features)

- VFD motors enabling wide levels of control for the mixer speed therefore better control of the particle size of the dried material

- Can be customized to include pulse back filters to reduce product loss during drying

- Thermal jackets to allow for optimal temperature controls. Not sure this is needed

- Ability to serve as a U1 pressure vessel

Processall maintains a fully equipped testing facility in Cincinnati, Ohio designed to provide customers with the data they need to develop their process, evaluate equipment, scale-up, and identify the necessary equipment to maintain desired production volumes. We extend an open invitation to all potential customers to bring their product to our test center and get a “hands on” experience with our technology and capabilities.

We also maintain a rental fleet that customers can utilize to do further testing at their facility or employ to minimize their startup costs for a new process.

Please feel free to contact us with all your material processing questions and our experienced industry professionals will help you find the right mixing solutions for your particular application.