With the international focus on waste reductions with the passing of treaties like the Paris Climate Accords, becoming an eco-focused business has become more vital to corporations’ long-term success. Consumers are demanding that the world become more carbon neutral by the day. It is, for this reason, proper waste disposal and waste reclamation projects are a growing market in today’s economy.

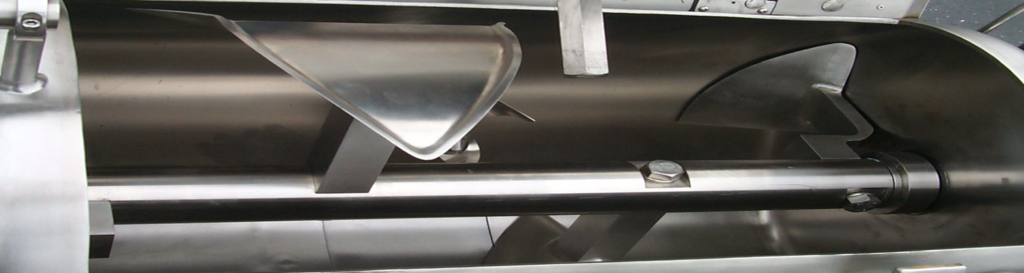

Processall’s industry experts have a long history of helping companies perform reclamation projects to recapture viable materials and capture the toxic byproducts of many applications to ensure proper disposals occur. Processall’s plow mixers are excellent at the extraction of hazardous chemicals thru methods such as steam stripping and vacuum drying. They also are efficient methods of removing organic solvents from materials and collecting them for either reuse or disposal. They have been able to remove chemicals upwards of 500% faster than other technologies on the market. Plow mixing technology has also been used to reclaim animal waste and sewage by reacting it with Sodium hydroxide to convert it into organic fertilizers. It has also been used to aid in the reclamations of coal ash and iron ores. Plow mixing technologies have even been used to aid in the concentration of nuclear waste to make the material easier to transport and dispose of long term.

Processall employees have a long history of working with companies in all markets aiding in everything from initial testing to installation of the unit to maintenance throughout the life cycle of the unit.

Processall’s plow mixing technology gives manufacturers a leg up on the competition. Listed below are some of the benefits of moving toward plow mixing technologies for waste reclamation operations.

- Faster extraction of organic wastes from the system than other methods

- Creation of a mechanically fluidized bed which reduces the extraction times

- Reduction in the energy required to extract chemicals

- A high-heat transfer rate within the vessel enables faster drying.

- A vessel jacket allows different media (hot oil, steam, or tempered water) to be used depending upon the thermal sensitivity of a product

- Adjustable pressure conditions enable both high-pressure applications and near-vacuum pressures to occur during different stages of the reaction.

- Allows for the collection of volatilized liquids

- Mill breaks up clumps and can be used for defining particle size

- Ability to agglomerate materials as fine as coal ash and convert them back into a viable fuel source for the coal industry

- Thermal jackets to allow for optimal temperature controls

- High-speed mix which can handle materials as fine as dried oats without damaging the material

- Easy to scale up and predict mix and drying times after lab testing

- Ability to remove hazardous solvents from material

- Vessels can be further outfitted to increase versatility:

- Mechanical seals – will allow the vessel to be pressurized as well as reach a low vacuum (28 Hg)

- Liquid lances – allows media to be sprayed onto a substrate

- Ability to perform the reaction and the mixing and drying within one unit resulting in:

- Faster throughputs

- Reduced energy consumption

- Smaller footprint on the production floor

Current uses of Plow mill technology in Waste Reclamation

- Sewage Reclamation

- Toxic Sludge Removal

- Coal Ash Slurries

- Nuclear Waste Concentration

- Flammable Sludges

- And many more

Processall maintains a fully equipped testing facility in Cincinnati, Ohio designed to provide customers with the data they need to develop their process, evaluate equipment, scale up, and identify the necessary equipment to maintain desired production volumes. We extend an open invitation to all potential customers to bring their products to our test center and get a “hands-on” experience with our technology and capabilities.

We also maintain a rental fleet that customers can utilize to do further testing at their facility or employ to minimize their startup costs for a new process.

Please feel free to contact us with all your material processing questions and our experienced industry professionals will help you find the right mixing solutions for your application.